Wind Energy

The Worldwide wind market is becoming a vital source of power generation with a lesser carbon footprint. JS Autocast has pioneered the design and manufacture of multiple castings such as Brake discs, Counterweight castings, yaw beams, labyrinth rings, torque arm supports, and Gear stay block assemblies for worldwide Wind applications and other rotating machinery.

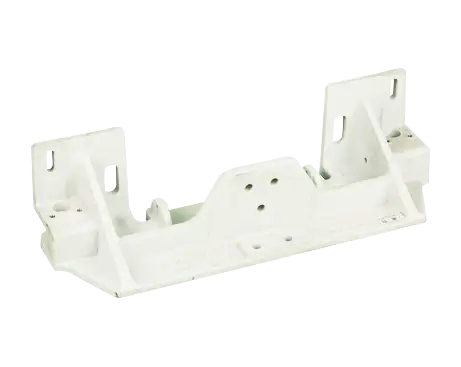

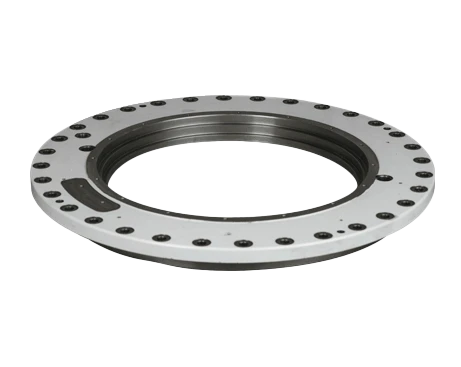

Brake Discs

Brake Discs

Brake Disc are components that are subjected to high mechanical and thermal loads. Certain factors, including spray water, road grime, and spreading material, influence the functionality and durability of the Brake Disc Casting. It is typical for the product to experience natural wear in the long run. It is crucial to ensure the working conditions of wind energy castings that determine the expectancy and workability of the braking system.

Technical Properties of Brake Disc Casting

Engineered to bear the developed mechanical stress due to the functioning of brakes, which creates pressure and tensile forces. Capable of resisting centrifugal forces when the wheels are running at higher speeds with thermal loads.

Uniform Thickness: Cast with precise dimensions and within the tolerance limit, maximizing the braking system performance and durability of the brake discs.

Braking Surface Ground or Fine: Manufactured to ensure a firm connection of the herd disc and continuous running operation.

Dimensional Tolerance: Discs are engineered within the defined tolerance limit to prevent the development of vibration in the brake disc.

Casting Hardness: The casting has the required hardness level, withstanding wear and tear.

Grey Cast Iron (pearlitic grey cast iron) is the most commonly preferred raw material to manufacture brake discs. Alloys play a vital role in enhancing their resistance properties. The combination of chrome and molybdenum in the iron castings uplifts wear, crack, and thermal resistance. Based on the technical requirements, raw materials with a high carbon content are added to the cast to achieve higher heat absorption. The manufactured Brake Disc meets the requirements of OE design, quality, and metallurgy. The Cast products are tested for defects, and the discs that pass the quality testing are made available to the market. JS Autocast is one of the Brake Disc Casting Manufacturers incorporated with advanced facilities to engineer brake disc of the defined specifications.

Working Principle

The working principle of the axle-mounted disc brake has a similar function to the conventional air brake system. When breaking is applied, its running speed gets reduced as the discs exert the brakes. Whereas, the applied brakes act on the wheel trade. The reduced pressure in BP maximizes the brake pressure in the cylinder and actuator. As a result, the Cast Iron Brake Disc gets clamped, which is attached to the axle, and forcefully stops the wheel.

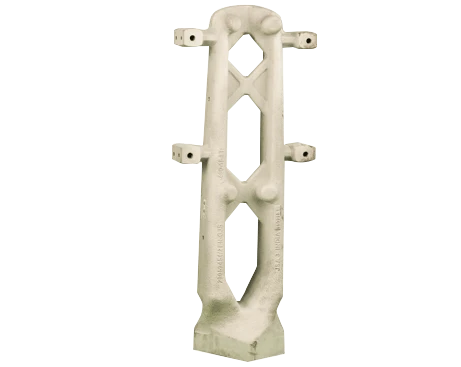

Counterweight Castings

Counterweight Castings

Counterweight Casting is a critical component and delivers supreme functionality in diverse applications, including construction, agriculture, and other industries. We have the best-in-class manufacturing facility that allows us to cast standard and tailor-made design detailing and specifications. We are highly proficient Manufacturer of Casting Counterweight products engineered exclusively for cranes, forklifts, kettlebells, marine buoys, elevators, and many more applications. We follow stringent quality testing methods to ensure the ductile iron counterweights are defect-free and meet international standards.

We are capable of Casting Counterweights for complex and distinctive structural detailing with more precision and accuracy. The design provision for slender areas to be cored is executed and results in results within the tolerance limit. The manufacturing technique deployed gives us a competitive advantage in engineering Cast Iron Counterweight with a smooth finished surface. We produce Cast Iron components in huge volumes, and the ideal die structure assisted us in reducing the operational cost. The preferences for sand centers and Die-casting primarily depend on the design detailing of the cast that resists forging.

When it comes to the overall cost, products made of Cast Iron are comparatively priced higher than the conventional technique of concrete counterweights. In terms of technical properties, Ductile Iron Counterweight Castings are the best choice. The density of the product is three times greater than that of concrete, which can be achieved with iron materials. It is critical to reduce the dimension of the product with the defined properties. Cast Iron leverages the advantage of retaining the defined quality, and meanwhile, the counterweight can be manufactured at a compact size. The estimated weight of the Castings is ensured with the minimal dimension, therefore reducing the accompanying volume of the product.

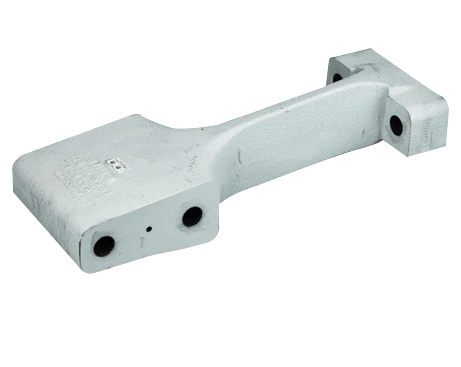

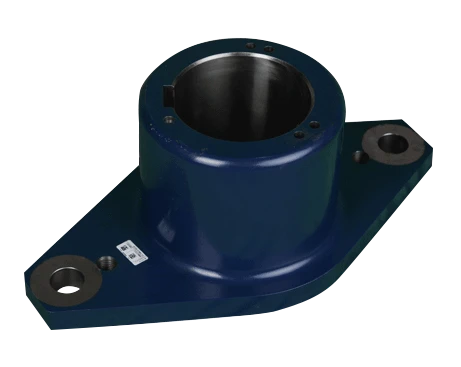

Torque Arm Supports

Torque Arm Supports

Torque Arm Support Cast iron

The torque arm support system is one of the critical components assembled in the turbine with suspension points. Mostly, the system is incorporated with the four points. The torque arm serves the purpose of eliminating structural-born noise isolation and reducing the dynamic torque transmission.

Typically, to meet the technical property requirements, the Torque Arm Support Cast Iron is designed and cast to have the physical form of a flat surface. The torque arm is supported with traditional multilayer sandwich mounts that are attached above and below the system, enhancing efficient functioning. Torque and turbine are the key factors in determining the structural detailing of the sandwich mount. Based on the requirements, the layers and dimensions of the sandwich mounts in the torque arm support system are designed.

The Cast Iron sandwich mounts of defined stiffness are designed and manufactured to upscale the productivity of the gearbox. The firm connection between the sandwich mount and torque arms is secured with various components. The installation of a mount under the torque arm is strongly preferred, which leverages optimizing the space and dimension. We have the production capability to cast the product of tailor-made specifications which allowed us to establish ourselves as the reliable Manufacturer of Torque Arm Support.

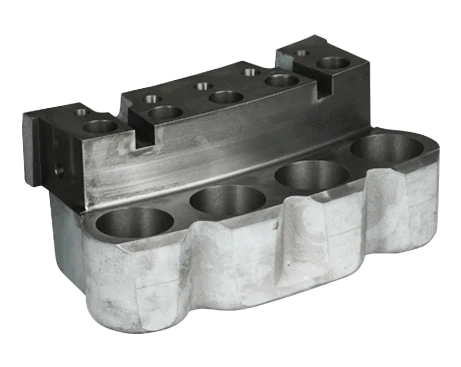

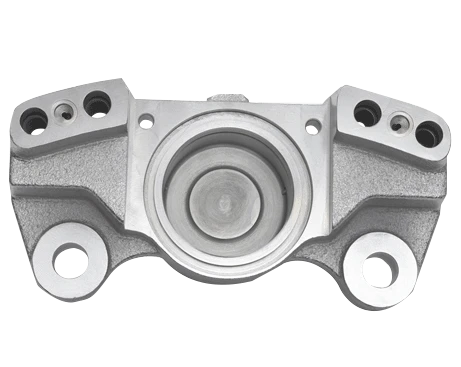

Labyrinth Rings

Labyrinth Rings

A labyrinth seal is a component designed to comprise two labyrinth rings. These rings overlap to secure a connection and enable the functioning of relative rotation with one another, leading to the assembly of labyrinth seal casting in the installed state. The wear resistance of the labyrinth rings differs due to the installation of labyrinth rings on mutually opposing surfaces.

Labyrinth seals are highly preferred in their fabrication and permit contact-free shaft seal function. The series of tooth placement enhances the sealing effect of the seal. The extension of the sealing path depends on the structural detailing of the rings. The effectiveness of the sealing relies on the Cast Iron Labyrinth Ring installation, which forges a tightly packed path on the shaft and on the fixed housing part. The seal rings castings are designed to rotate in a relative direction for higher sealing productivity. The constricted sealing path between the labyrinth ring castings ensures a very minimal tolerance for fluid leakage. The chances of a seal leak due to the working condition are eliminated to the greatest possible extent by incorporating the directed mass flow.

The Cast Iron Labyrinth Rings are manufactured with higher precision and within the defined tolerances to retain the efficiency of the labyrinth seal. There are possibilities to influence the functioning of the seal when the rings of imperfect dimension are attached to the component. Therefore, it leads to the creation of unwanted contacts with the assembly of the shaft and housing part. The external loading during the operation is the primary reason behind the failure of seals and the improper functioning of the cast iron rings. We, the Casting Manufacturer, ensure every stage of the casting process for quality testing.

Other Applications

Agriculture

Manufacturing castings for the agricultural segment needs specialized expertise to meet the desired requirements.

View More

Off-Highway

The Off-Highway industry relies highly on large equipment and vehicles for operations and transportation.

View More

Automotive

The rapidly growing automotive industry in India is one of the largest in the world and it continues to grow at an incredible pace.

View More

Oil & Gas

Each and every equipment in the oil and gas Industry are designed and manufactured with a chosen quality as it is the major contributor to the world economy.

View More